RECLAIM OUR ENVIRONMENT

THE GLOBAL AQUATICA STORY

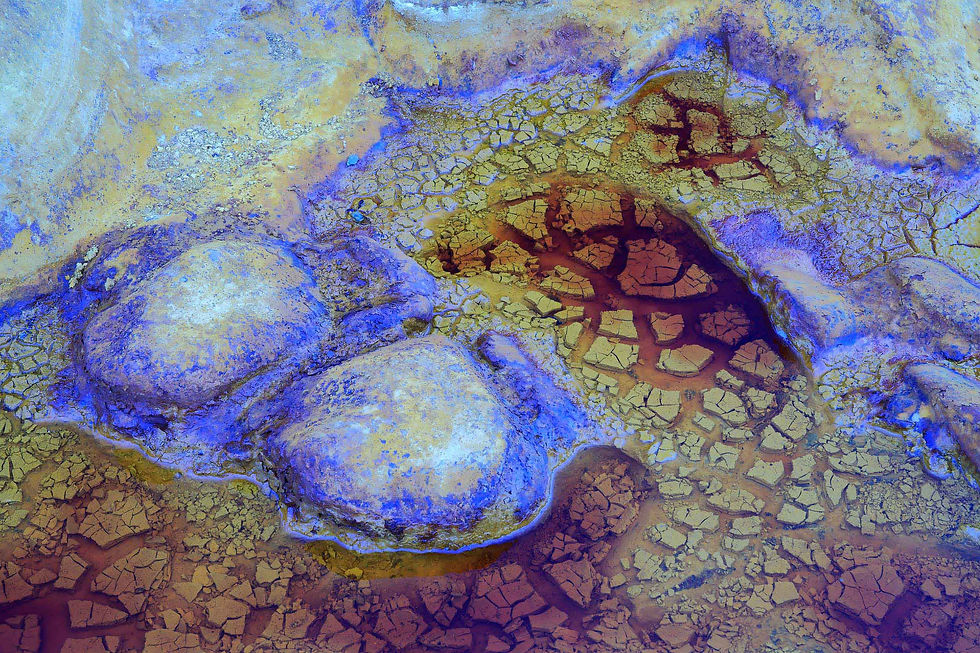

Our story begins with a global problem, as engineers we understand the issues of Acid Mine Drainage (AMD) with costs to the mining sector and governments running into the billions of dollars each year. AMD is a serious global problem. This unwelcome mining by-product produces high concentrations of sulfuric acid, iron, aluminum, arsenic, and other heavy metals, which create widespread ecological destruction, water table contamination, and infrastructure damage.

Working collaboratively with industry, government and environmental bodies we have developed a solution to eliminate AMD. Since 2014 we have been rigorously testing our patented BioAqua technology, successfully operating to eradicate AMD at our test sites located in Australia.

There are two key elements which make our solution unique. Firstly, the water is cleaned to higher standards than current available technologies. Secondly, recovery of minerals and sulphates extracted during the process means we can deliver our solution through a viable economic model. BioAqua is both economically and environmentally sound.

Acid Waste Water

Acid Mine Drainage

What is Acid Mine Treatment

Acid Mine Treatment

Waste Water

AMD, MEET BIOAQUA

Acid Waste Water

Acid Mine Drainage

What is Acid Mine Treatment

Acid Mine Treatment

Waste Water

Global Aquatica provides technology and services to clean water polluted by industry. Our first product, BioAqua, has been developed specifically for the mining sector.

BioAqua is a total solution that fully remediates acidic, sulphate, and metal contaminated water, eradicating the contamination at its source. The system produces high quality water, without imported chemicals or requiring waste to be stored. It also delivers a cost-effective solution as the materials removed from the water can be sold generating revenue. This means mining and government clients can earn revenue while cleaning the environment and eradicating contamination.

BioAqua also totally eradicates the causes of acidic waste water such as tailings, acid producing waste rock and lime treatment waste sludge.

THE BIOAQUA SOLUTION

WORLD FIRST

Uses recycled green waste, which is then converted into nutrients for the bacteria that power our remediation process.

H2-WOW

Produces better quality water than existing processes, sulphate levels are reduced to better than EPA requirements.

RESELL & RECYCLE

Extracts and harvests heavy metals from the contaminated water for sale, and water is recycled.

LOW COST

Substantially lower CAPEX and OPEX than alternatives, reducing the risk for our clients, while minimising expensive mining bonds.

LONG LIFE

Increases the lifespan of a mine, boosting profits while continuing to remediate the environment.

NEW REVENUE

Enables a mine to earn while also eradicating harmful waste.

Acid Waste Water

Acid Mine Drainage

What is Acid Mine Treatment

Acid Mine Treatment

Waste Water

Although the product was developed specifically for the mining sector, the process can also be applied to:

FURTHER APPLICATIONS

-

Treatment of soil with high levels of acid sulphates, which can be a particular problem in farming regions

-

Treatment of oil and grease contamination

-

Treatment of water with high sulphate levels

-

Treatment of water contaminated with heavy metals

REMEDIATION PACKAGE

Global Aquatica provides a complete remediation package. We will be delivering an end-to-end service for our customers which will involve a six step process:

1 / INVESTIGATE

Our Global Aquatica engineers carry out site surveys and analysis of water chemistry.

2 / INSTALL

We construct a pilot plant at our cost to confirm the BioAqua waste management service, reducing the risk for our clients.

3 / RUN PILOT

Operate as a reduced capacity full size plant to minimise initial capex.

4 / SCALE UP

Custom manufacture (off-site) and on-site assembly of full scale operation.

5 / MANAGE

Ongoing management of the water and ensuring consistent service

6 / VALUE ADD

Sale of the recyclable materials and eradicate the causes of the waste water such as tailings, waste rock and lime dosing sludge.

OUR JOURNEY SO FAR

From day one we have continued to innovate, expand and refine our BioAqua technology, consistently hitting key industry and commercial milestones along the way. Our journey to help reclaim the environment from the ecological devastation that is AMD has only just begun.

Highlights have included our success in receiving a $1million Australian Federal Government grant through the Accelerating Commercialisation Program and construction of a pilot plant at Mount Morgan Mine in Rockhampton.